Kipsta, supplier of the official Uber Eats Ligue 1 and BKT Ligue 2 ball, for the 2022-2027 period

As a result of the consultation launched in March 2021, the Board of Directors of the LFP has designated Kipsta, Decathlon group's football brand, as the new official supplier of the LFP.

Kipsta premium footballs, designed in France, have been awarded the FIFA Quality Pro label and undergo quality tests at various stages of production.

With the official balls of the Uber Eats Ligue 1 and BKT Ligue 2, Kipsta wishes to demonstrate its know-how at the highest level of competition.

Too light? Too heavy? The weight is standardised...

Ball weight: Between 410 and 450g (Size 5)

How big is it? What's the circumference?

Ball circumference: Between 68 and 70 cm (size 5).

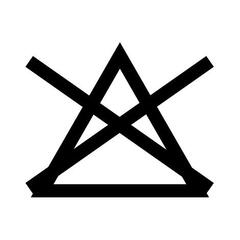

A "round" ball?

Average measured variation: maximum of 2%.

We measure the football's sphericity at 4500 different points and then examine any differences.

If the discrepancy is greater than 2% (FIFA PRO Standard), our engineers are tasked with improving the sphericity to ensure a consistent bounce.

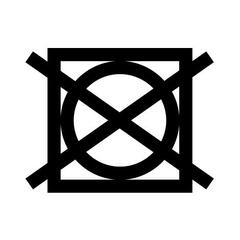

Maximum pressure loss test: here's what we do...

We inflate the ball to the recommended pressure (meaning 0.8 bar).

72 hours later, the ball must not lose more than 15% of its pressure, meaning approx. 0.1 bar. The pressure after 72 hours must, therefore, be at approx. 0.7 bar.

This also means that it is quite normal for a ball to lose pressure after a few days.

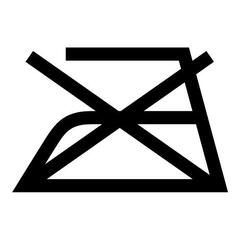

We've also tested how much water the ball absorbs...

We simulate rainy playing conditions in a lab, leaving the ball to sit in 2 cm of water on a pivoting support whilst subjecting it to 250 compressions.

By the end of the test, this ball must not have absorbed more than 15% of its weight, or approx. 65 g for size 5.

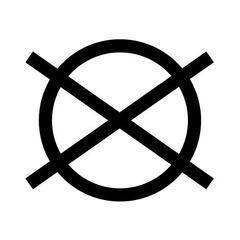

It's all about the bounce

Between 125 and 155 cm (size 5) with a maximum difference of 10 cm between the ball's highest and lowest bounce. Each ball is dropped 10 times on a steel plate from 2 metres in height.

Not even a scratch!

The most demanding test that this ball is subjected to is the machine shot test.

The ball must resist up to 2500 shots against an inclined flat concrete slab at 50 km/h at a distance of 2.5 m.

At the end of the test, we check:

- the ball's general state: the stitching must withstand this test.

- the circumference: it must not have increased by more than 1.5 cm.

- the sphericity: it must not have varied by more than 2%.

- the pressure: loss of pressure must not exceed 15%.

How about you? What do you think?

We value your feedback and use it to continuously improve our products.A huge thank you in advance for sharing your feedback with us.